In the production of the chemical coating industry, there are pain points such as product foaming, cracking, peeling, and oxidation. However, traditional drying technologies have excessively high investment and operation costs, making "low-cost drying" an urgent issue to be solved.

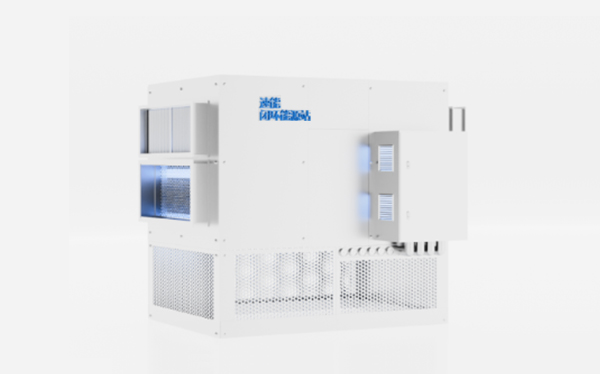

The thermal energy closed-loop energy station uses a small amount of electricity to collect waste heat and gas, converting them into high-temperature dry hot air for the production line to heat up and boost efficiency. It saves up to 70% energy compared to traditional drying methods while improving productivity.

It eliminates exhaust emissions, reducing air pollution to zero, and can liquefy organic solvents to realize waste gas recycling. As a new energy solution for drying systems, it achieves energy and material closed loops, making it an efficient, energy-saving and eco-friendly new equipment.

Integrated Process

Mature technology with innovative integrated treatment process.

New Material Application

Corrosion-resistant and anti-leakage, successfully applied in industrial thermal energy recovery projects with safe and reliable quality.

Economic Plan

Provide accurate technical and total economic cost analysis reports for process schemes.

Informatization Management

Industrial informatization management system ensures project quality progress and realizes visualized delivery.

Modular Manufacturing

Engineering modules can be assembled in a building-block manner (movable, detachable and upgradable).

National Service Hotline

Website: www.sunerjs.com

Email: suner@sunerjs.com

Address: Nanotechnology Industrial Base, Chinese Academy of Sciences, No.128 Fangzhou Road, Suzhou Industrial Park, Suzhou, Jiangsu, China

Copyright © 2024 Suner Thermal Energy Technology (Jiangsu) Co., Ltd All rights reserved