With rising energy costs and increasingly stringent environmental regulations, a chemical plant is under enormous pressure to save energy and reduce emissions. Its traditional energy utilization methods result in massive waste heat emissions, which not only increase operational costs but also severely impact the environment. To improve production efficiency and reduce carbon emissions, the plant decided to introduce advanced heat recovery technologies to enhance energy utilization, lower production costs and achieve environmental goals.

With rising energy costs and increasingly stringent environmental regulations, a chemical plant is under enormous pressure to save energy and reduce emissions. Its traditional energy utilization methods result in massive waste heat emissions, which not only increase operational costs but also severely impact the environment. To improve production efficiency and reduce carbon emissions, the plant decided to introduce advanced heat recovery technologies to enhance energy utilization, lower production costs and achieve environmental goals.

Energy saving and consumption reduction: The project has successfully improved waste heat gas recovery efficiency by 70%, significantly reducing the plant's energy consumption and reliance on external energy sources.

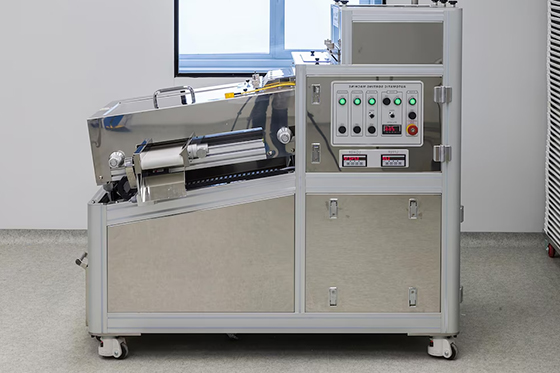

Suner's closed thermal energy station, using advanced heat exchange technology, efficiently recovers and utilizes waste heat from production. Heat in exhaust gas is quickly absorbed and converted into high-temperature dry hot air, which is then delivered via duct systems to production links requiring heat. Compared with traditional heat recovery systems, Suneng's system achieves over 70% recovery efficiency, significantly reducing external energy consumption.

Suner's closed thermal energy station, using advanced heat exchange technology, efficiently recovers and utilizes waste heat from production. Heat in exhaust gas is quickly absorbed and converted into high-temperature dry hot air, which is then delivered via duct systems to production links requiring heat. Compared with traditional heat recovery systems, Suneng's system achieves over 70% recovery efficiency, significantly reducing external energy consumption.

[Executive editor]: Suner Thermal Energy Technology (Jiangsu) Co., Ltd

Copyright: Suner Thermal Energy Technology (Jiangsu) Co., Ltd Please indicate the source when reprinting

National Service Hotline

Website: www.sunerjs.com

Email: suner@sunerjs.com

Address: Nanotechnology Industrial Base, Chinese Academy of Sciences, No.128 Fangzhou Road, Suzhou Industrial Park, Suzhou, Jiangsu, China

Copyright © 2024 Suner Thermal Energy Technology (Jiangsu) Co., Ltd All rights reserved