Isenthalpic heating source, referred to as dry heat source, adopts energy cycle technology to realize infinite recycling of sensible heat and latent heat of energy, greatly saving energy consumption in production and daily life. This technology is mainly used for air flow drying, such as fluidized bed, boiling drying. Various product drying, coating machines, etc. It converts moisture or organic substances in the production process from gaseous state to liquid state through isenthalpic process, and the released heat is used for reheating the drying gas. Generally, it can raise the temperature from ambient temperature to above 100℃.

Energy cannot be created out of nothing, nor can it disappear into nothing. By adopting energy closed-loop circulation technology, only the starting energy is needed to supplement the energy loss during operation.

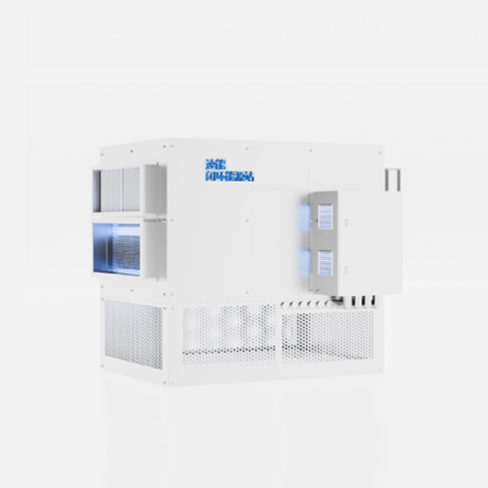

| Product Name | High-Temperature Closed-Loop Energy Station | |||||

| Model | SUN2800HT | SUN4000HT | SUN5000HT | SUN6000HT | SUN10000HT | SUN20000HT |

| Air Volume m³/h | 2800 | 4000 | 5000 | 6000 | 10000 | 20000 |

| Supply Air Temperature ℃ | 122 | 122 | 122 | 122 | 122 | 122 |

| Supply Air Humidity %RH | 1.61 | 1.61 | 1.61 | 1.61 | 1.61 | 1.61 |

| Supply Air Outlet Flange Size (Length × Width) mm | 750×550 | 910×524 | 910×524 | 910×524 | 1400×600 | 2×1400×600 |

| Return Air Temperature ℃ | 90 | 90 | 90 | 90 | 90 | 90 |

| Return Air Humidity %RH | 10 | 10 | 10 | 10 | 10 | 10 |

| Return Air Inlet Flange Size (Length × Width) mm | 750×550 | 910×524 | 910×524 | 910×524 | 1400×600 | 2×1400×600 |

| Input Power kw | 12.5 | 19.2 | 21.4 | 28.8 | 46.2 | 92.5 |

| Power Supply | 380v/3H/50Hz | 380v/3H/50Hz | 380v/3H/50Hz | 380v/3H/50Hz | 380v/3H/50Hz | 380v/3H/50Hz |

| Control System | Touch Screen + PLC Programmable Controller | |||||

| Equipment Functions | Heat Recovery, Dehumidification, Exhaust Display, Supply Air Heating, Exhaust Air Cooling | |||||

| Heat Recovery Energy kw | 59.1 | 90.9 | 104.4 | 136.2 | 218.9 | 437.8 |

| Heat Recovery Efficiency COP | 4.7 | 4.7 | 4.9 | 4.7 | 4.7 | 4.7 |

| Dehumidification Capacity kg/h | 56.9 | 87.5 | 100.5 | 131.1 | 210.7 | 421.4 |

| Specific Moisture Extraction Rate kg/kw | 4.6 | 4.6 | 4.6 | 4.6 | 4.6 | 4.6 |

| Equipment Overall Dimensions (Length × Width × Height) mm | 1760×1118×1770 | 2160×1418×1970 | 2160×1418×1970 | 2260×1518×2070 | 3326×1955×2540 | 2×3326×1958×2540 |

| Equipment Weight kg | 1140 | 1400 | 1520 | 1730 | 1950 | 3900 |

National Service Hotline

Website: www.sunerjs.com

Email: suner@sunerjs.com

Address: Nanotechnology Industrial Base, Chinese Academy of Sciences, No.128 Fangzhou Road, Suzhou Industrial Park, Suzhou, Jiangsu, China

Copyright © 2024 Suner Thermal Energy Technology (Jiangsu) Co., Ltd All rights reserved